Ordinary printing ink uses solvent to dry ink, drying time depends on printing material and climate which could makes drying process slower. Solvent using could effect the enviroment

UV ink contains complex of dynamic monomers and coloring agents

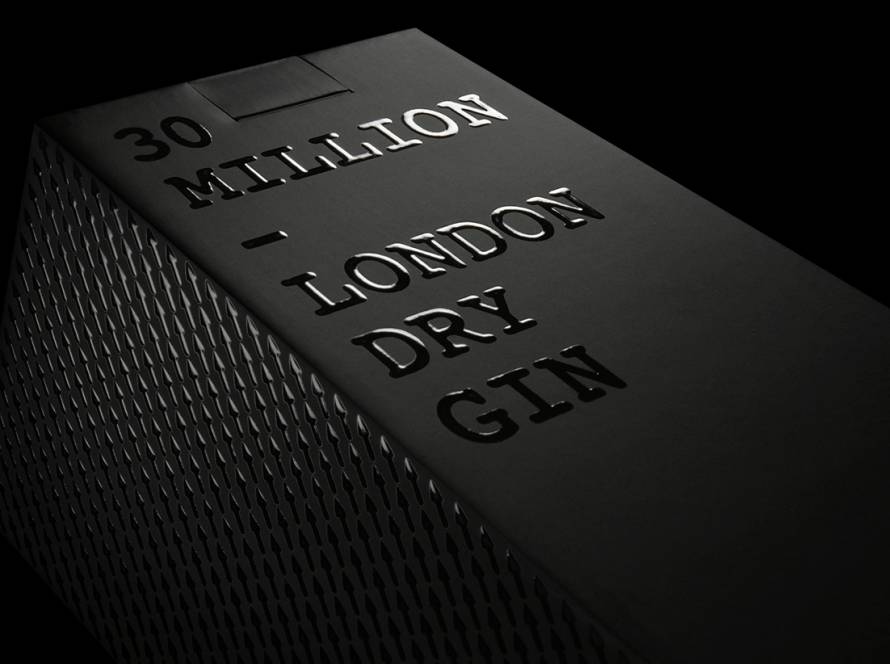

Oil-based UV printing ink allows ink to adhere to various materials such as: paper, fabric, wood, glass, plastic,...Therefore, it makes UV printing technology turns into a well known method in advertising industry. Every banner, light box, logo, braille banner are UV printing products

Ordinary printing ink uses solvent to dry ink, drying time depends on printing material and climate which could makes drying process slower. Solvent using could effect the enviroment. UV ink contains complex of dynamic monomers and coloring agents

Oil-based UV printing ink allows ink to adhere to various materials such as : paper, fabric, wood, glass, plastic,...Therefore, it makes UV printing technology turns into a well known method in advertising industry. Every banner, light box, logo, braille banner are UV printing products

After each printing unit, UV ink will be dried by UV drying system, almost instantly dry after exposing, which saves time for the next printing product. Post-production is very sharp, color fastness without spreading or obscuring, creating unique noteworthy, attractive, vivid and reliable impact

Exceptionally, UV Printing Ink permits straightforwardly print on material surface without covering prior to printing, bringing homogeneous shading which is simpler to control than other printing inks